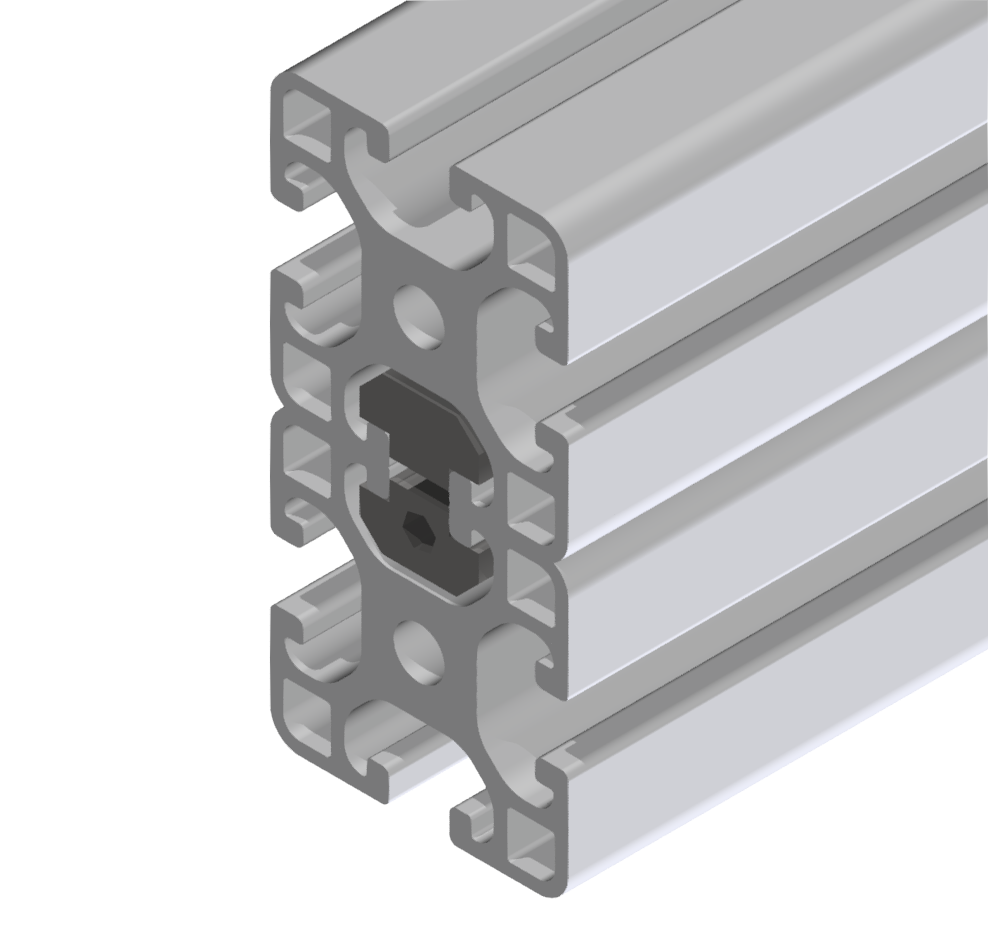

Connection of parallel profiles: Stable constructions for your aluminum profile systems

The connection of parallel profiles is an essential component of modern aluminum profile systems. This technique makes it possible to fix two or more profiles at a defined distance from each other, which forms the basis for extremely stable and versatile structures.

Parallel connectors are used in numerous areas of industry and mechanical engineering. They are ideal for:

- Construction of frames and racks

- Creation of workstations and workbenches

- Construction of conveyor systems and transport equipment

Advantages

The main advantage of this connection technology is its flexibility and load-bearing capacity. The parallel arrangement of the profiles achieves optimum force distribution, which increases the overall stability of the structure.

Technical details

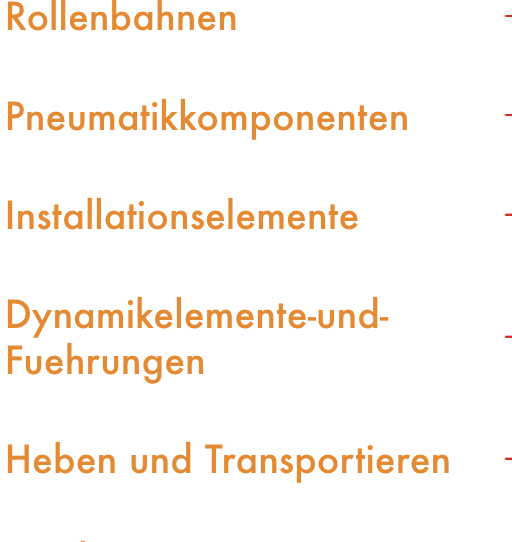

Modern parallel connectors, such as parallel connector 8, offer the following features:

- Simple installation without profile machining

- Pre-assembled clamping screws for quick installation

- Defined profile spacing (e.g. 12 mm for parallel connector 8)

- Compatibility with common profile systems (e.g. Series 8)

FAQ: Connection of parallel profiles

Here you will find answers to frequently asked questions about the connection of parallel profiles.

What types of parallel connectors are there?

There are various types, such as the parallel connector 8 or the parallel connector 8-21, which differ in size and area of application.

Are special tools required for installation?

Usually not. Many modern parallel connectors are designed so that they can be installed without special tools or profile machining.

How resilient are parallel connections?

The load capacity depends on the connector and profiles used. In general, parallel connections offer high stability and are suitable for demanding constructions.

Can parallel connectors be released subsequently?

Yes, most systems are easy to dismantle, which ensures flexibility for conversions or extensions.