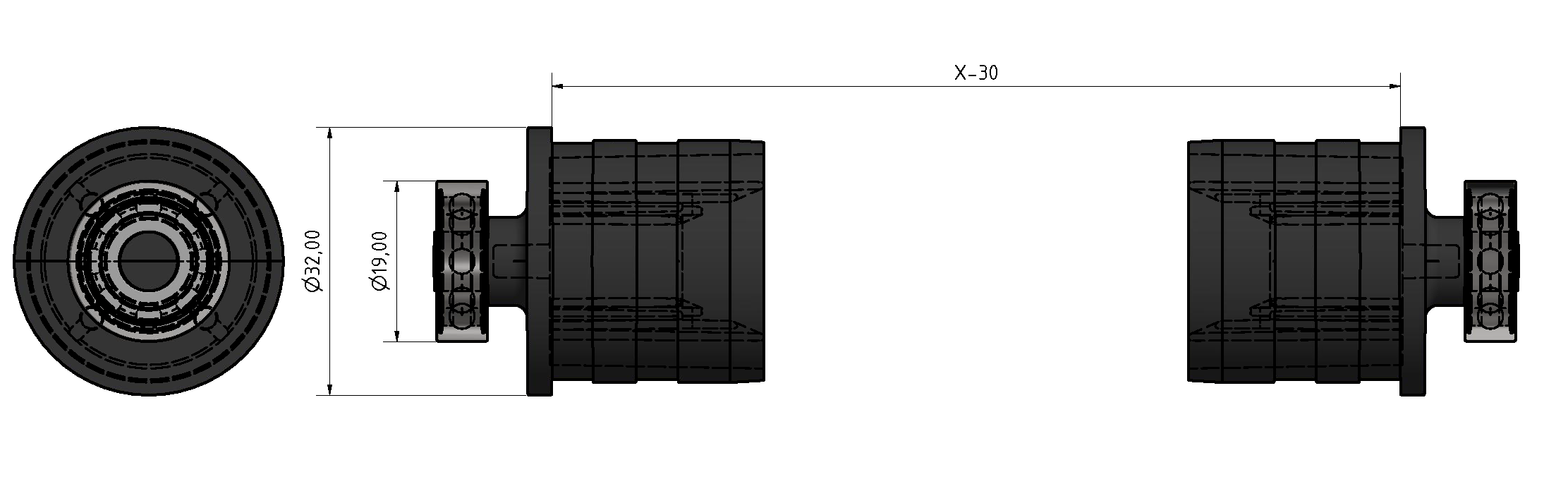

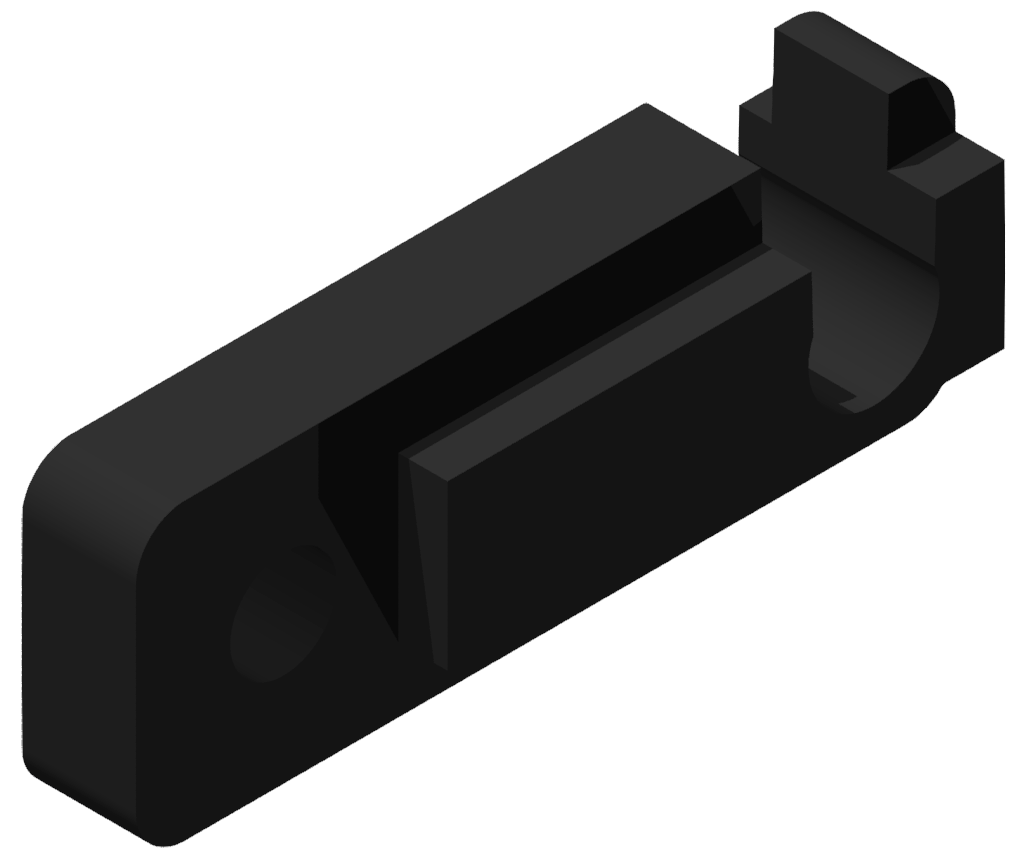

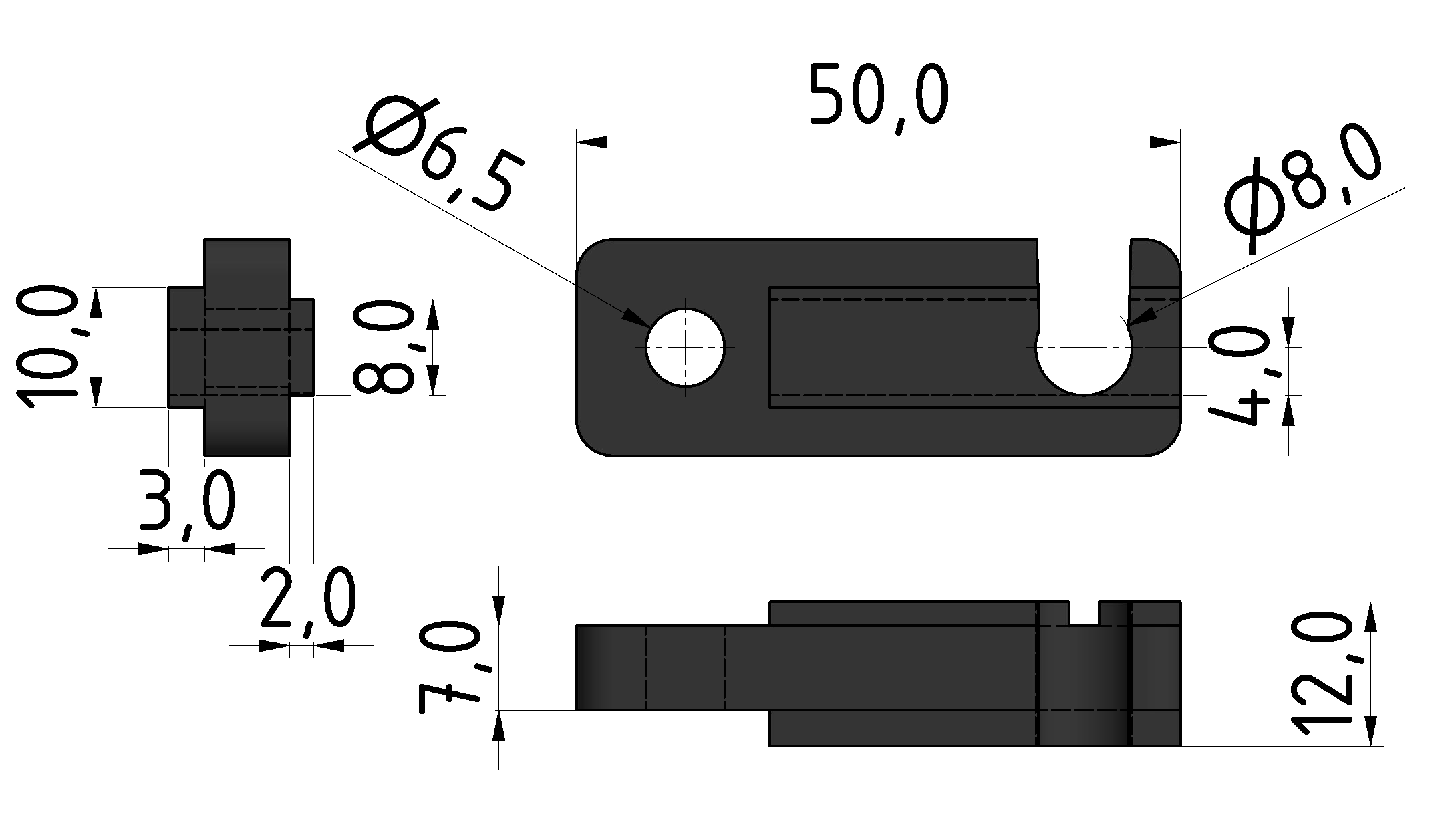

Conveyor technology: Efficient solutions for internal material flow

Conveyor technology forms the backbone of modern logistics and production. At maunsystem, you will find high-quality conveyor technology solutions that optimize your operational processes and increase your productivity.

Customized solutions:

We offer a wide range of conveyor technology, including:

- Roller conveyors

- Chain conveyor

- Belt conveyor

- Lifting tables

- Vertical conveyor

Our experts will be happy to advise you to find the optimum solution for your specific requirements.

Versatile applications:

Our conveyor systems are suitable for transporting a wide variety of goods – from general cargo to bulk goods and pallets. They are used in warehouses, production halls and distribution centers.

Increased efficiency:

With our conveyor technology, you can optimize your material flows, reduce manual handling and increase the throughput of your systems.

Quality and reliability:

maunsystem stands for robust, durable conveyor technology that works reliably even under demanding conditions.

Frequently asked questions about conveyor technology

Here you will find answers to frequently asked questions about conveyor technology.

What is the difference between continuous and discontinuous conveyor technology?

Continuous conveyor technology, such as belt conveyors, transports material without interruption. Discontinuous systems, such as forklift trucks, move goods in individual cycles.

What role does conveyor technology play in intralogistics?

Conveyor technology is a core component of intralogistics. It enables the efficient transport of goods within warehouses and production facilities and is crucial for optimizing material flows.

How can conveyor technology contribute to automation?

Modern conveyor technology can be equipped with control systems and sensors to implement automated processes. This enables precise control of the material flow and a link to higher-level warehouse management systems.

What safety aspects need to be considered with conveyor technology?

Important safety aspects include protective devices on moving parts, emergency shutdowns and ergonomic design of operating elements. Regular maintenance is also crucial for safe operation.

How can conveyor technology contribute to energy efficiency?

Modern conveyor technology uses energy-efficient drives and intelligent control systems to optimize energy consumption. Conveyor systems can also be designed to recover energy, for example when braking loads.