Guide shafts: Precision and stability for your linear systems

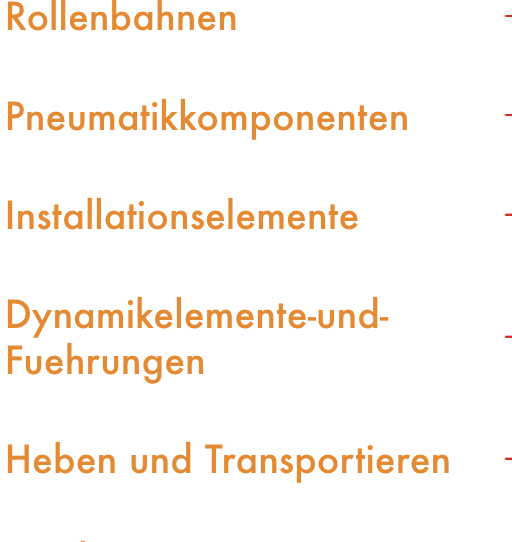

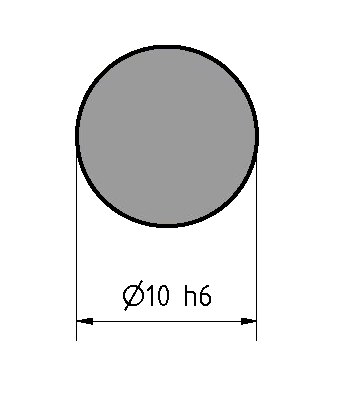

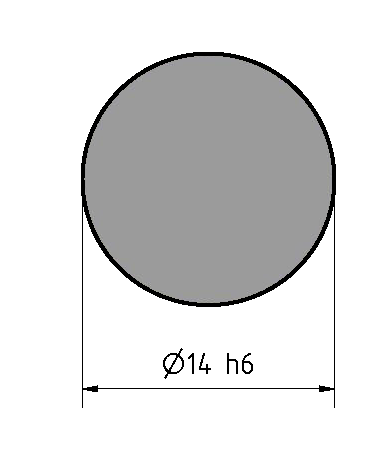

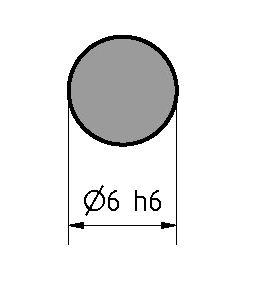

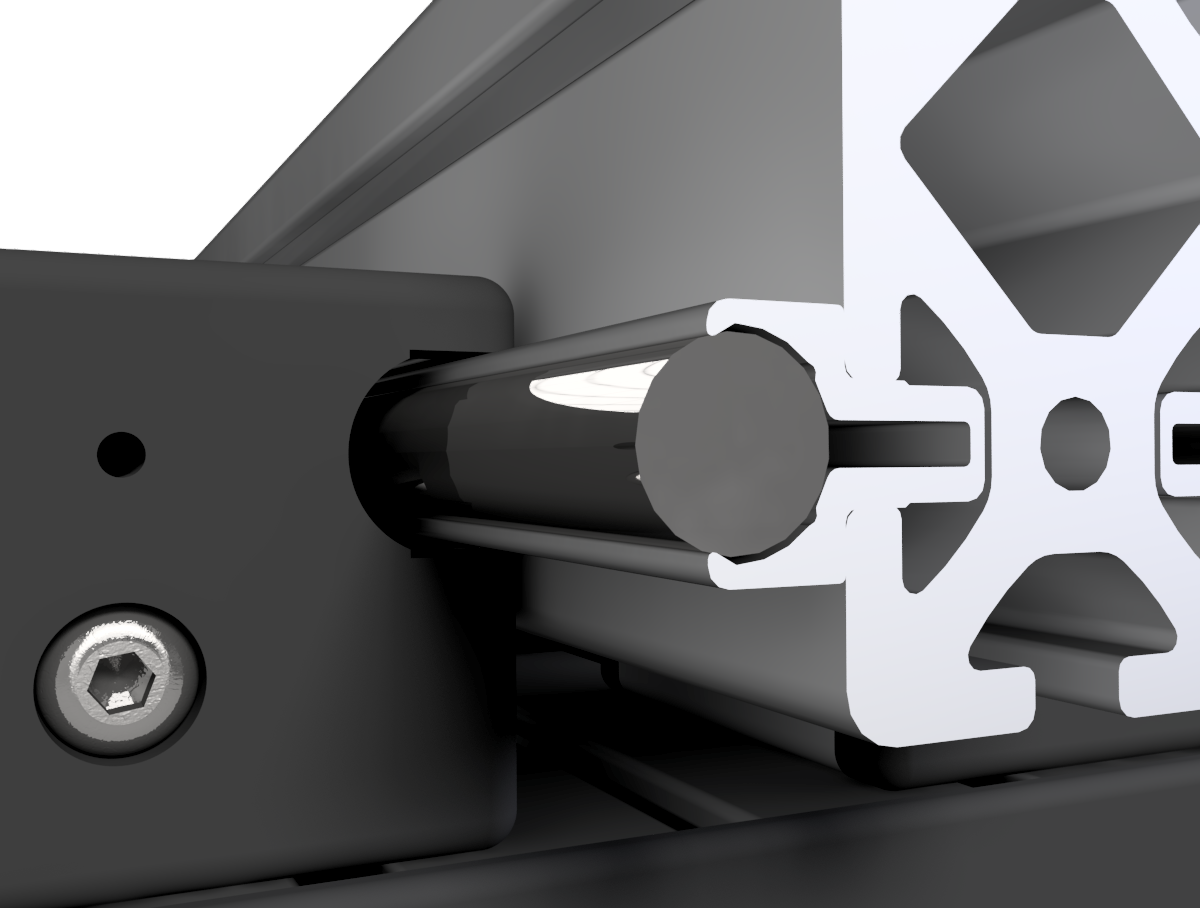

Our hardened and ground guide shafts are indispensable components in linear technology and offer maximum precision for your applications. They can be used in a variety of ways for the construction of linear guides, roller guides, recirculating ball bearing elements, C-rails, ball sleeve guides and ball sleeve block guides. At maunsystem you will find a wide selection of high-quality guide shafts for a wide range of applications. Our shafts are also available with a coating for increased corrosion protection.

Our guide shafts are ideal for:

- High-precision ball bearing guides

- Linear systems and positioning systems

- Precision mechanical engineering

- Automation technology

Features of our guide shafts

- Induction hardened for uniform hardness and wear resistance

- Finely ground surface for optimum running properties

- High roundness and parallelism for precise guidance

- Available in various materials such as heat-treated steel and stainless steel

Advantages of maunsystem guide shafts

- Extensive range of different diameters and lengths

- Compatible with standard guide bushes and linear ball bearings

- Customized solutions on request

- Fast delivery and expert advice

FAQ on guide shafts

Here you will find answers to frequently asked questions about our guide shafts.

What is the difference between guide shafts and linear shafts?

Guide shafts and linear shafts are basically the same thing. Both terms describe precision-machined steel shafts that are used as guide elements in linear systems.

What materials are used for guide shafts?

Guide shafts are typically made of heat-treated steel or stainless steel. Stainless steel guide shafts are particularly suitable for corrosive environments or in the food industry.

How are guide shafts attached?

There are various mounting options for guide shafts, including versions with an internal thread or special mounting holes.