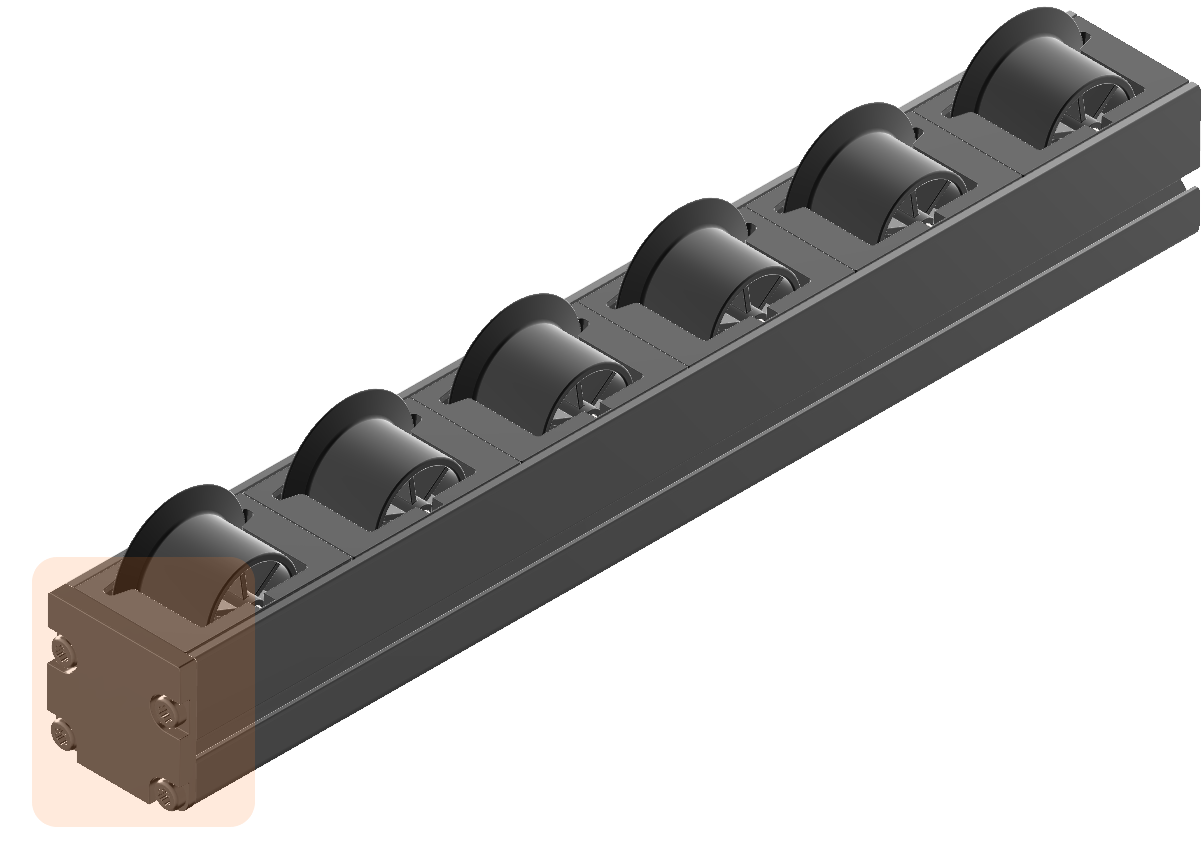

Roller conveyors: Efficient conveyor technology for your production

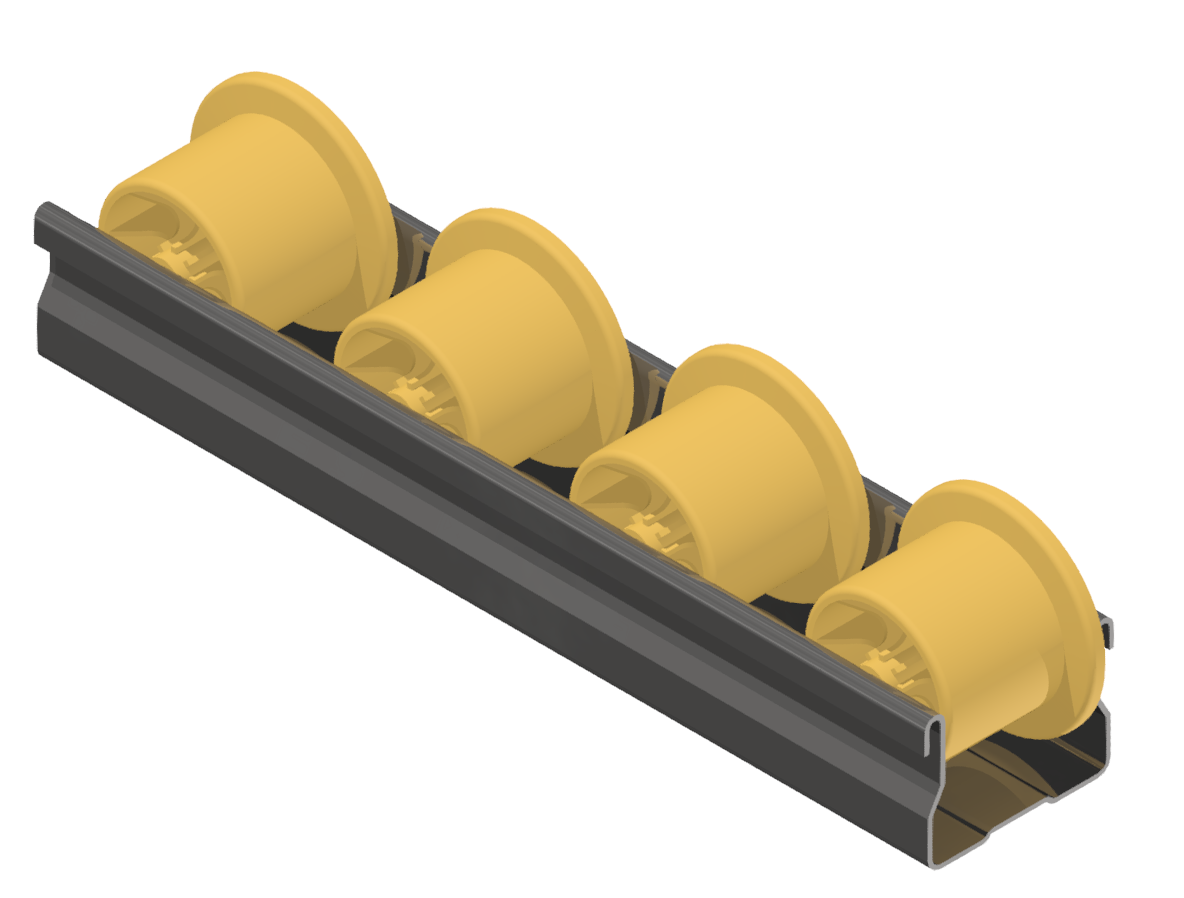

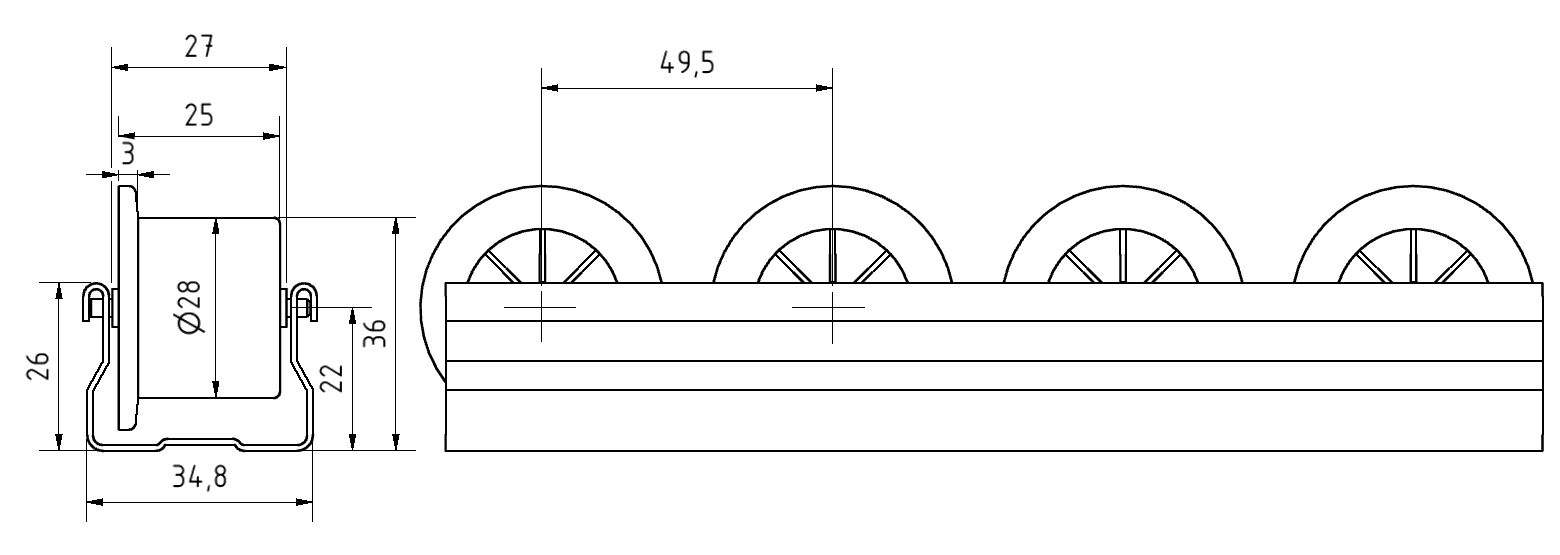

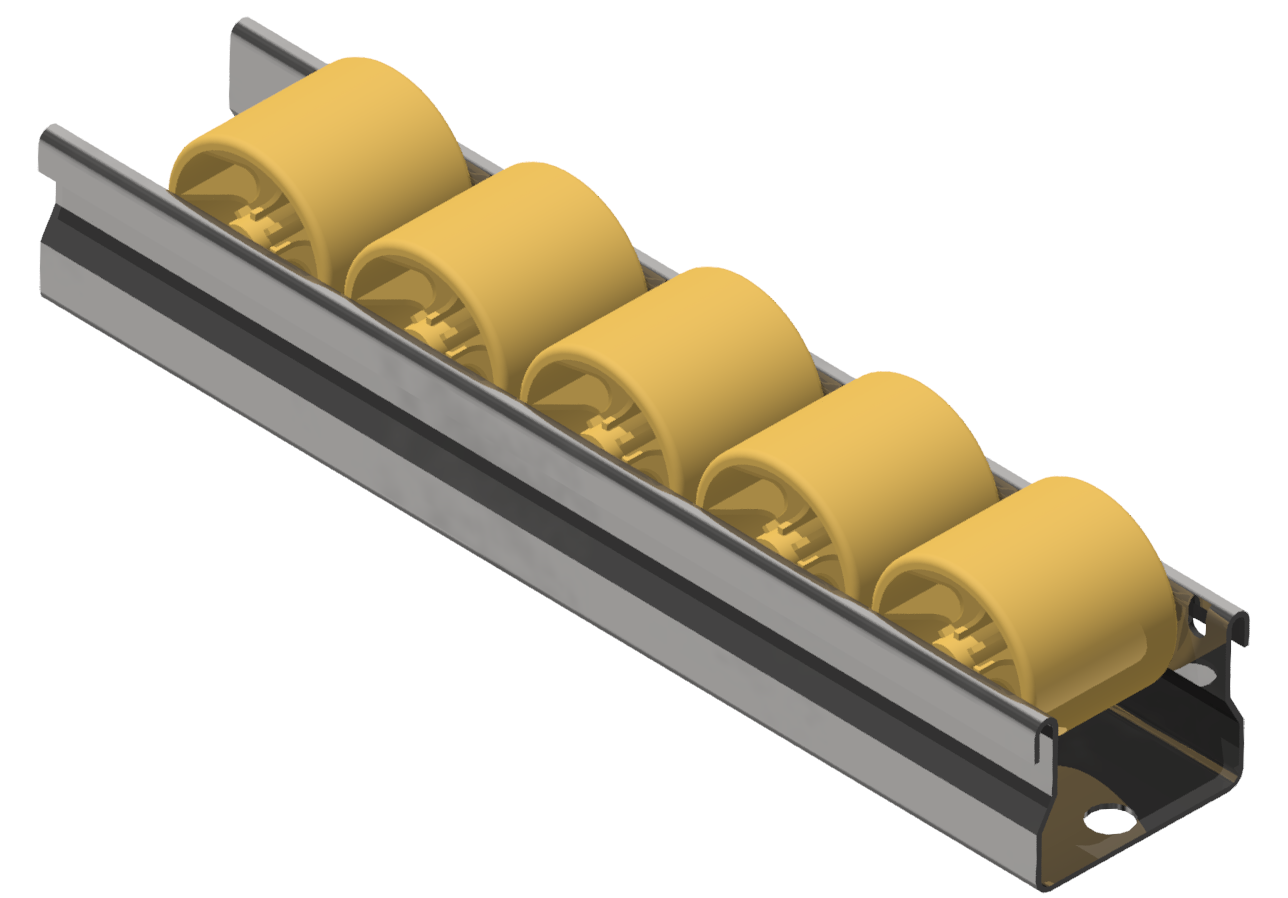

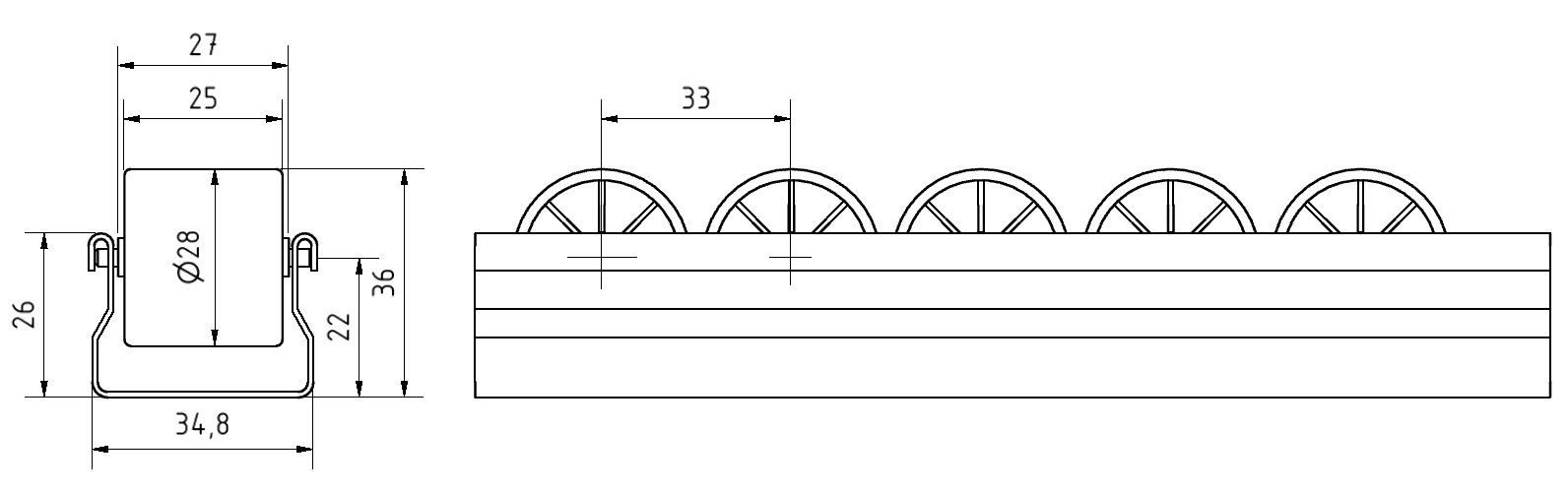

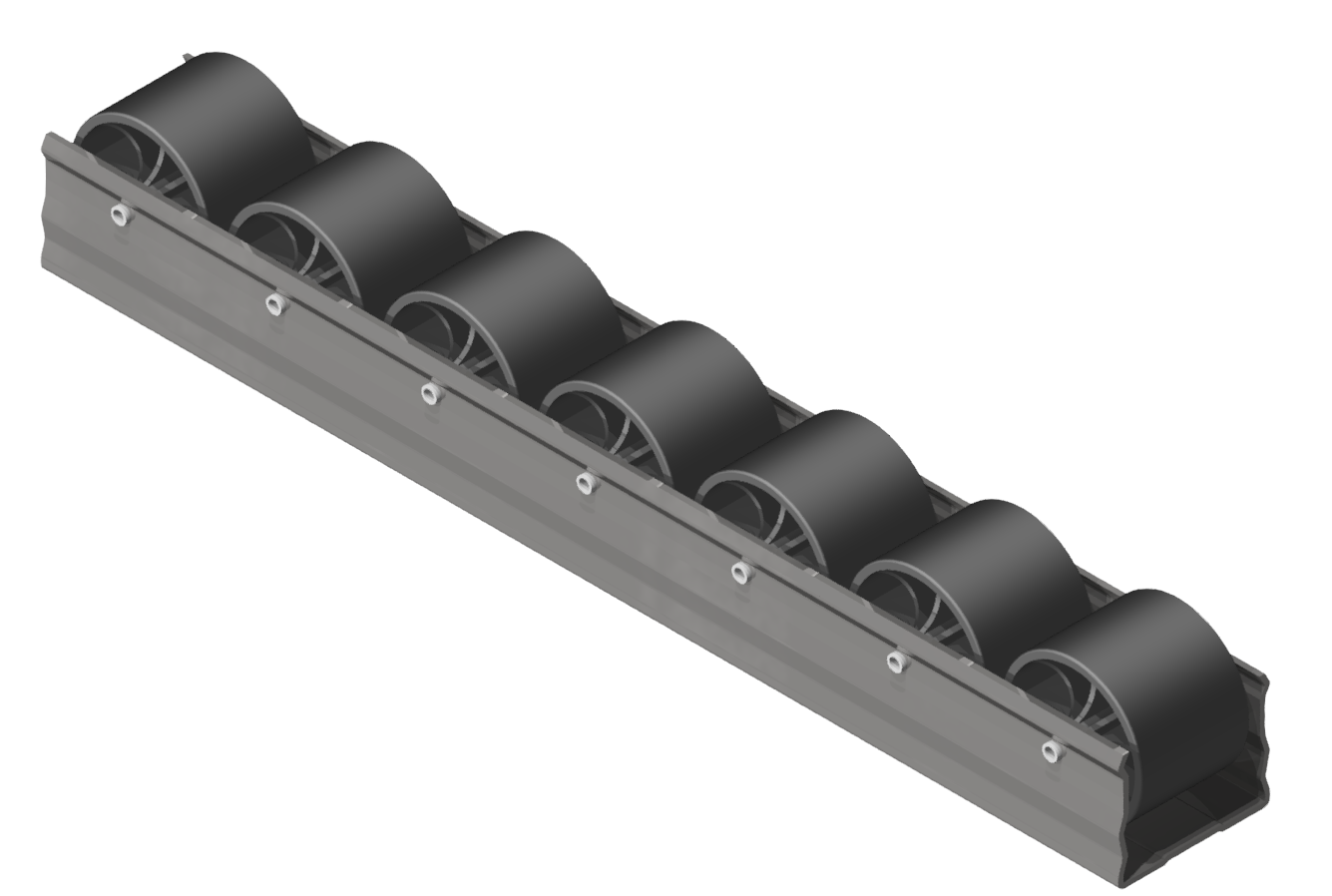

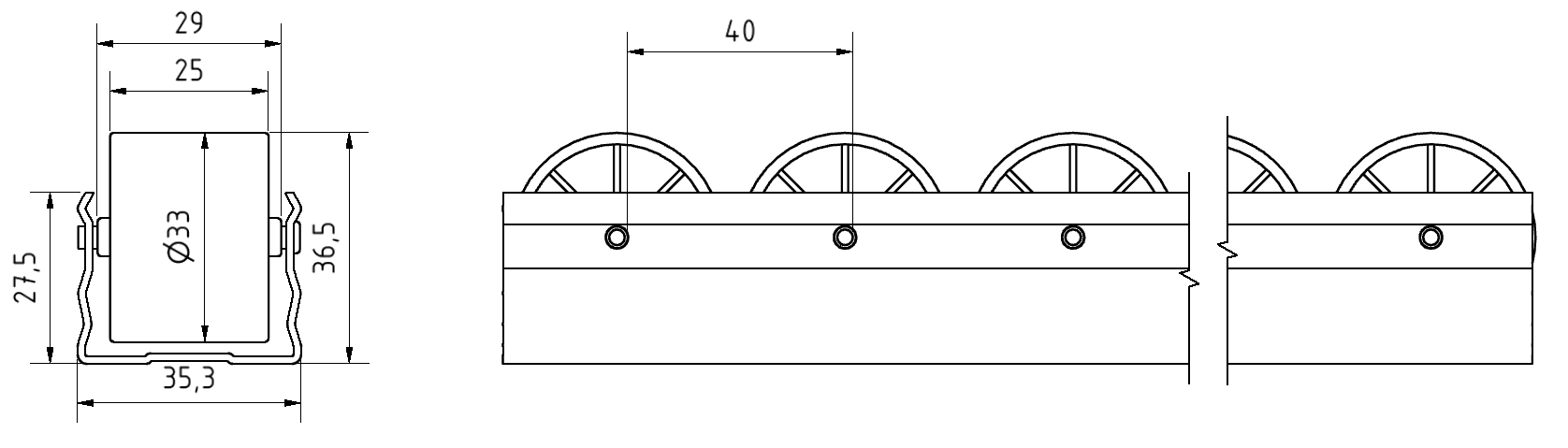

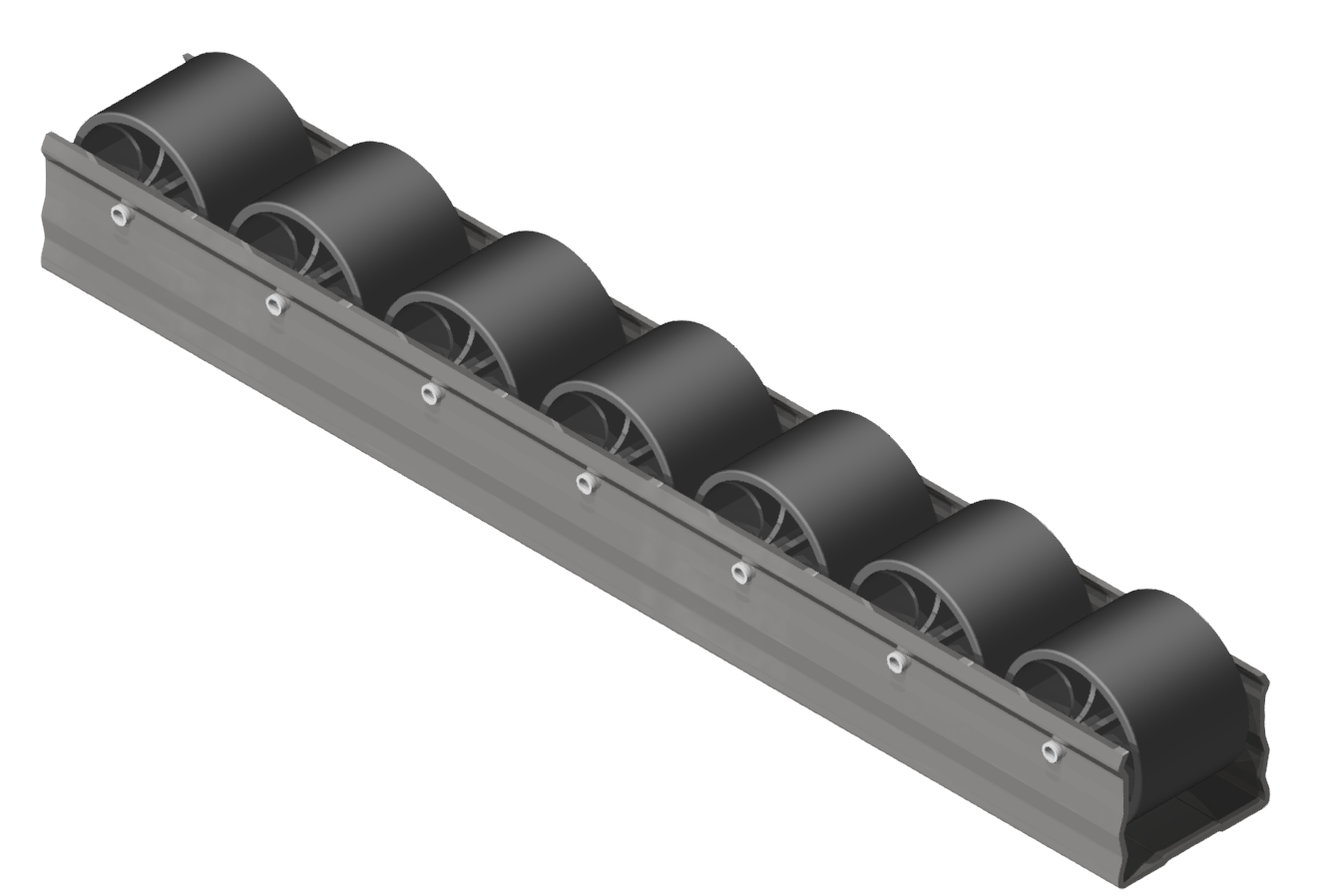

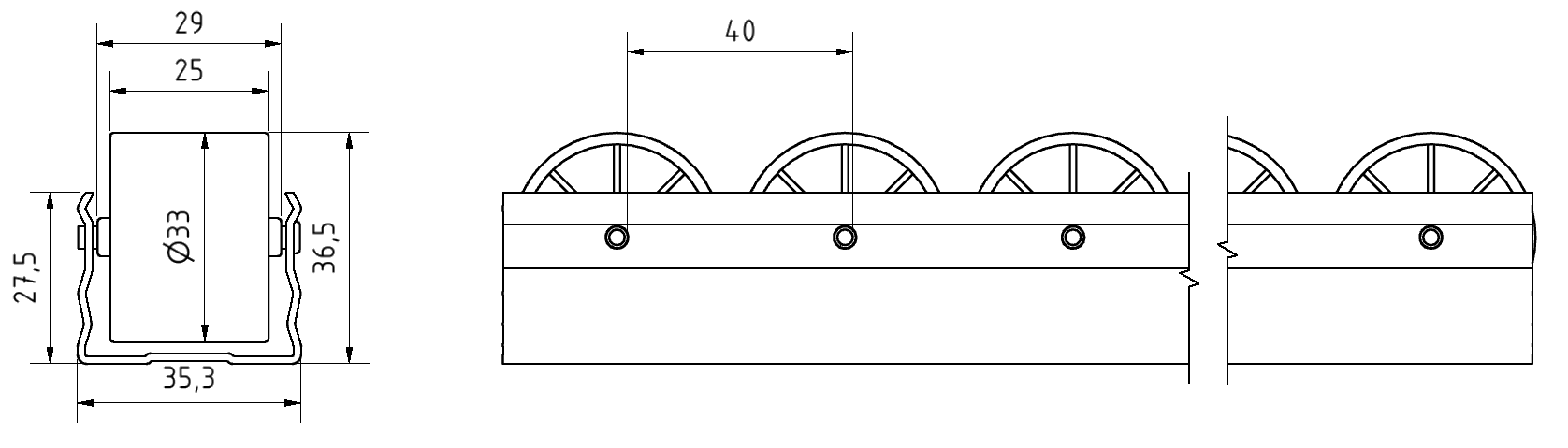

Roller conveyors for aluminum profiles are indispensable components of modern conveyor technology and offer efficient transport solutions in production facilities and warehouses. They enable a smooth material flow and are ideal for setting up conveyor lines and buffer stations. These robust and durable systems are available in various sizes and configurations to meet different requirements. Easy integration into existing systems and modular customization options improve efficiency and productivity in industry and logistics.

Our roller conveyors are suitable for a wide range of applications:

- Production lines

- Assembly workstations

- Packaging stations

- Storage systems

- Picking areas

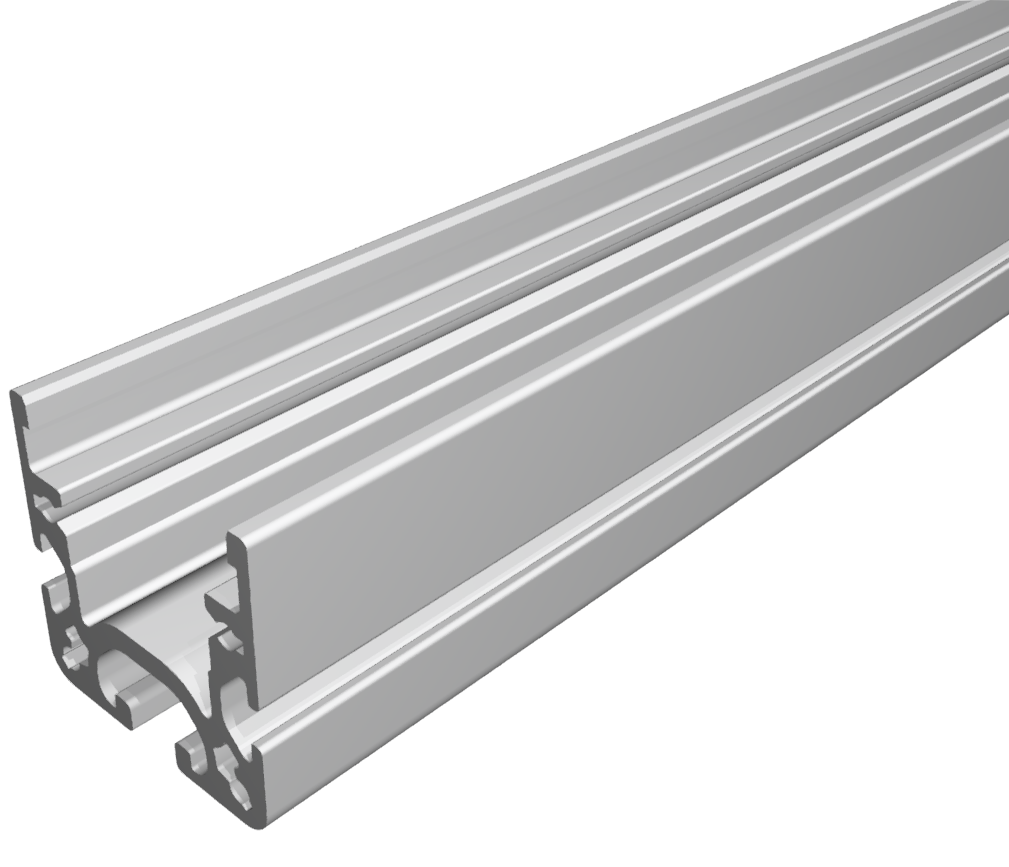

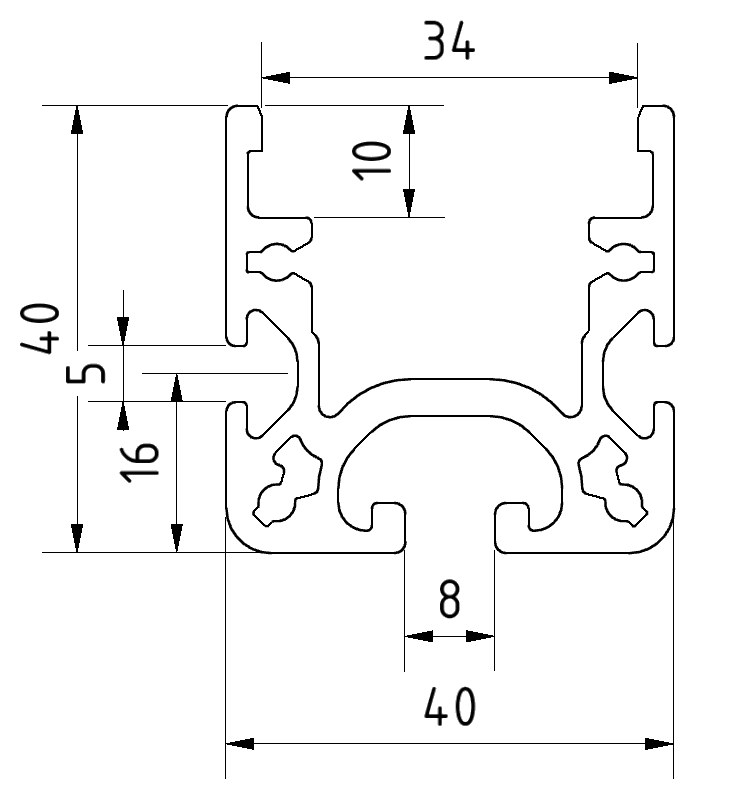

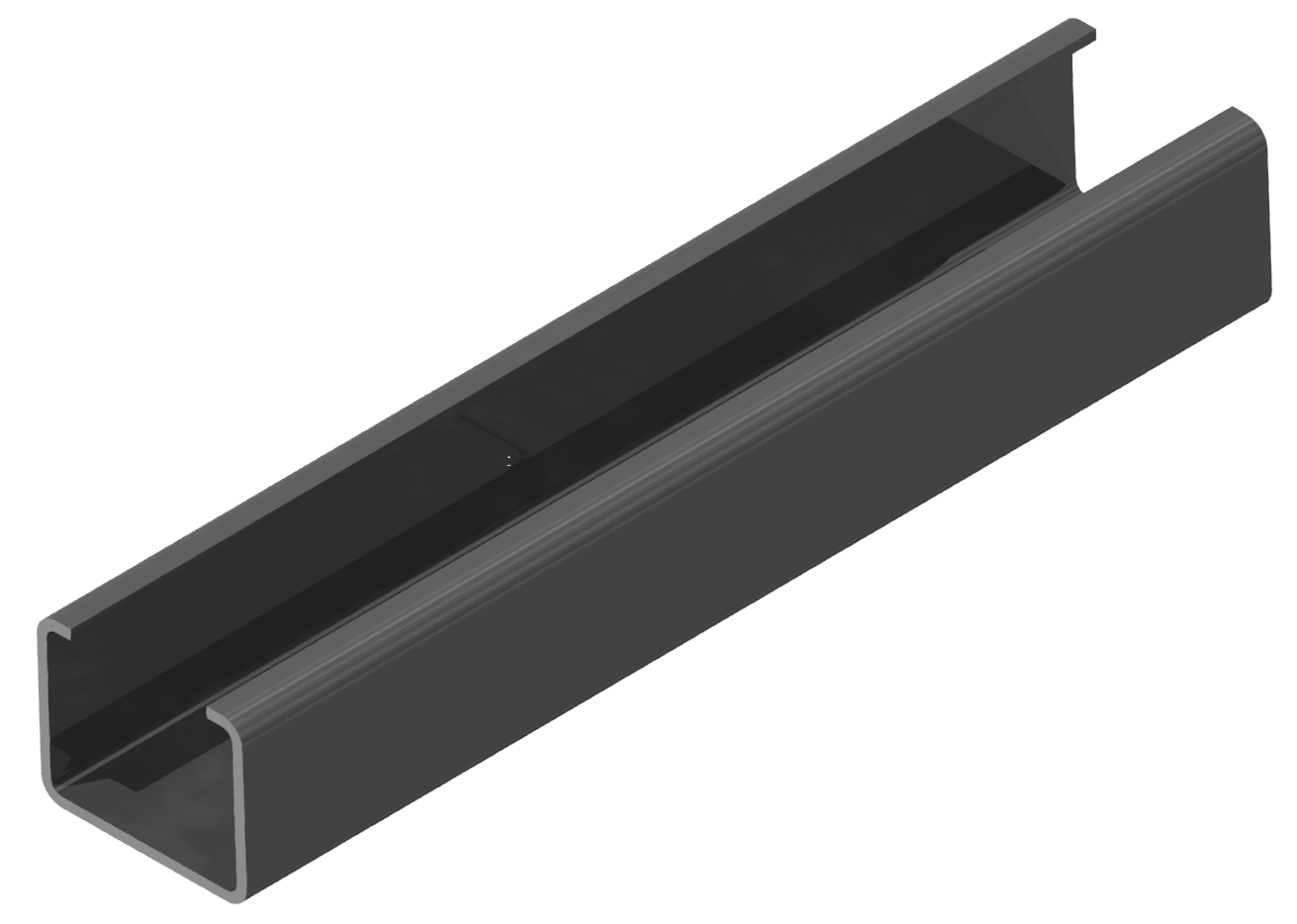

By using robust aluminum profiles, we guarantee maximum stability and durability combined with low weight.

Modular design for maximum flexibility

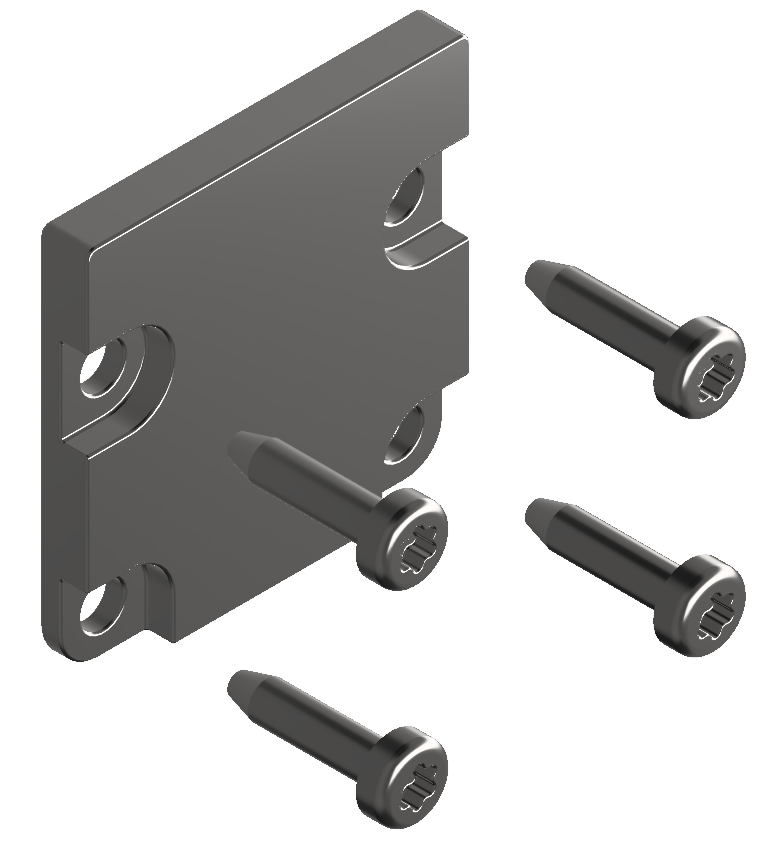

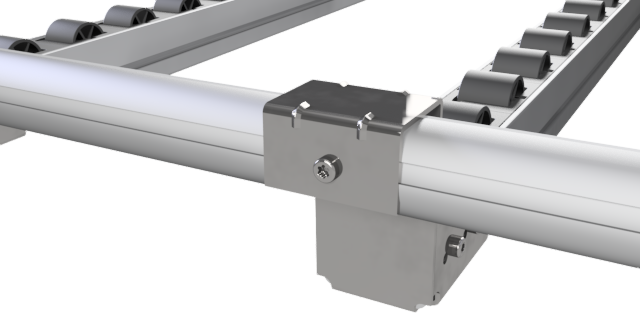

The modular design of our roller conveyors makes it easy to adapt them to your individual requirements. Whether straight sections, curves or complex conveyor systems - our compatible profile systems allow a wide range of configurations to be realized.

Focus on ergonomics and efficiency

Thanks to the optimum design of the working height and smooth integration into your workplace systems, our roller conveyors help to improve ergonomics. This leads to an increase in productivity and employee satisfaction.

Compatibility and quality

Our roller tracks are fully compatible with common profile systems such as item aluminum profiles and Bosch aluminum profiles. This means you can easily expand existing systems or implement new systems cost-effectively.

FAQ: Frequently asked questions about roller conveyors

Here you will find answers to frequently asked questions about our roller conveyor systems.

What is the difference between roller conveyors and conveyor belts?

Roller conveyors consist of individual, rotating rollers, while conveyor belts have a continuous belt surface. Roller conveyors are particularly suitable for heavier goods and allow easy manual handling.

What are the advantages of modular roller conveyor systems?

Modular systems allow flexible adaptation to changing production processes, simple extensions and cost-effective redesigns. They also simplify maintenance and repairs.

Can roller conveyors be integrated into existing LEAN concepts?

Yes, our roller conveyors are ideal for LEAN production environments. They support efficient material flows and can be easily integrated into Kanban systems or just-in-time processes.

How high-maintenance are roller conveyors?

Modern roller conveyors require very little maintenance. Regular cleaning and occasional re-greasing of the bearings are usually sufficient for long-term reliable operation.

Are customer-specific adaptations possible?

Absolutely. Thanks to our modular system and in-house CNC production, we can realize tailor-made solutions for your specific requirements.

Discover the variety of our roller conveyors and conveyor technology solutions. Contact us today for an individual offer and optimize your material flows with maunsystem.