Lean Production: Efficient process optimization for modern production systems

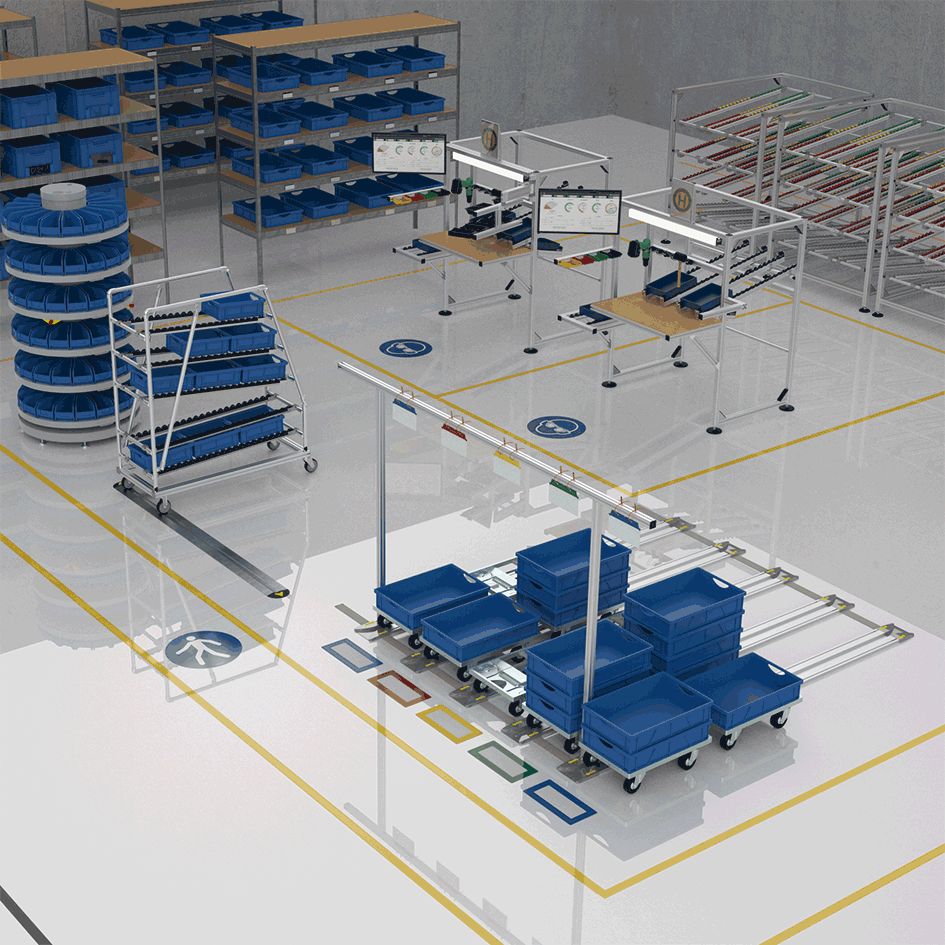

Lean production, also known as lean manufacturing, is an innovative concept for optimizing manufacturing processes. It aims to increase efficiency and minimize waste. In today's Industry 4.0 era, lean production, often referred to as Lean 4.0, is becoming increasingly important.

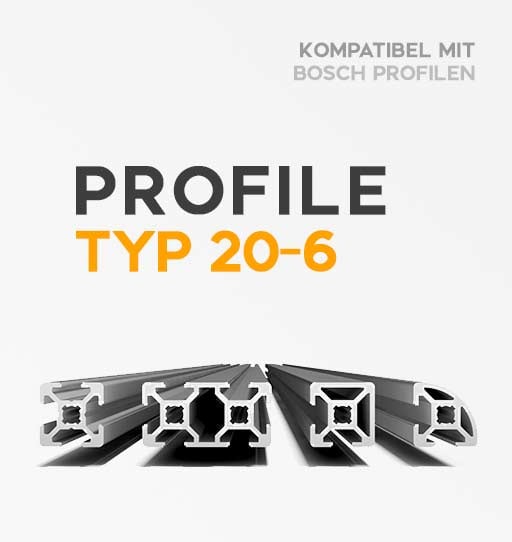

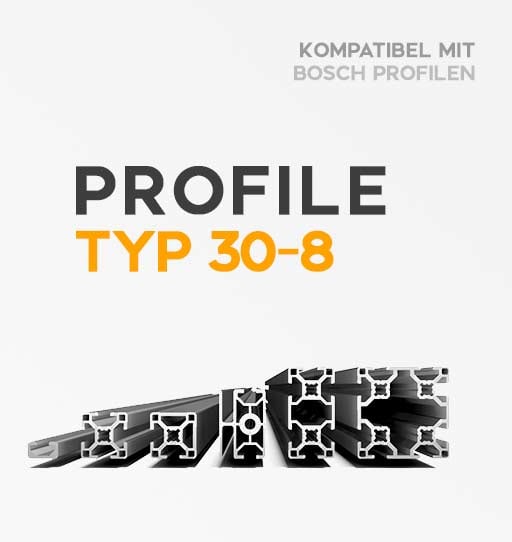

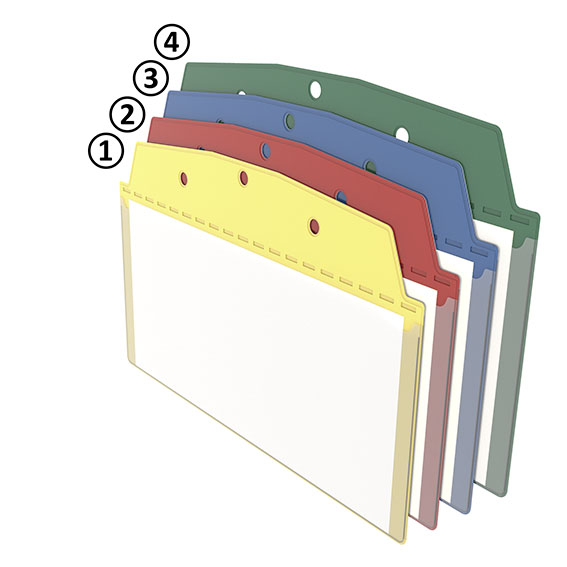

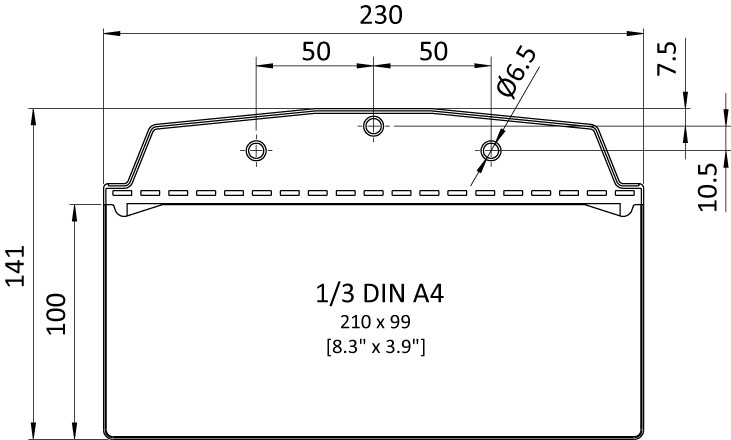

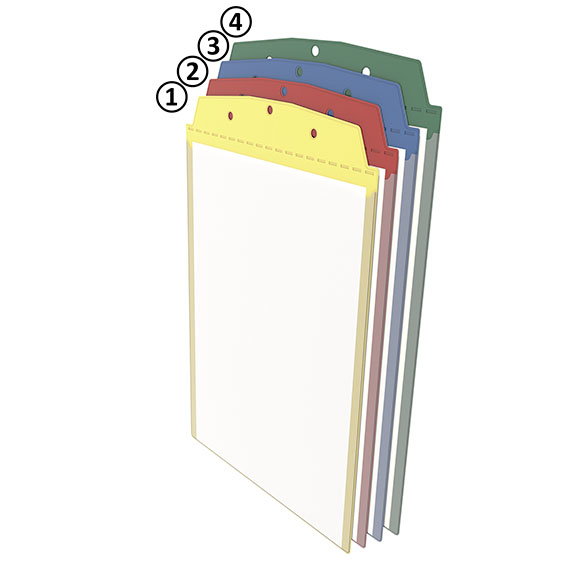

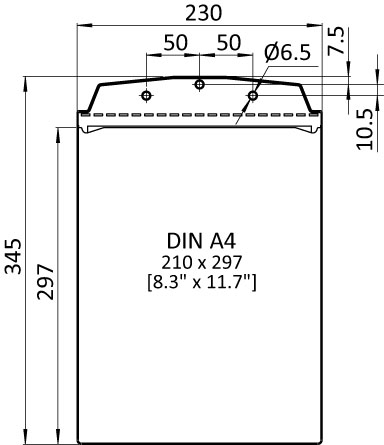

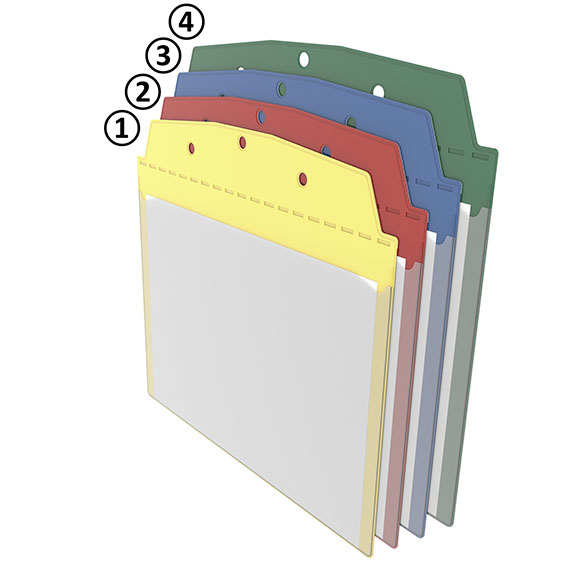

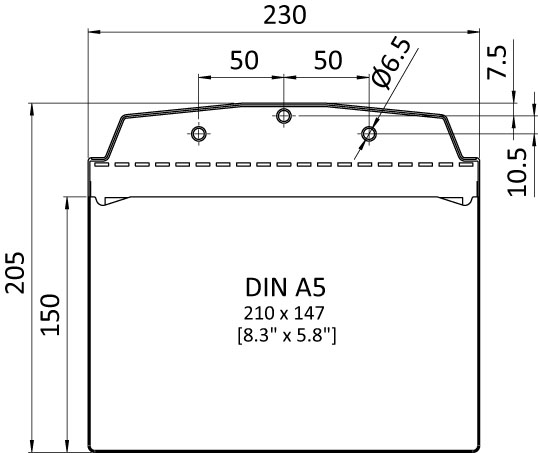

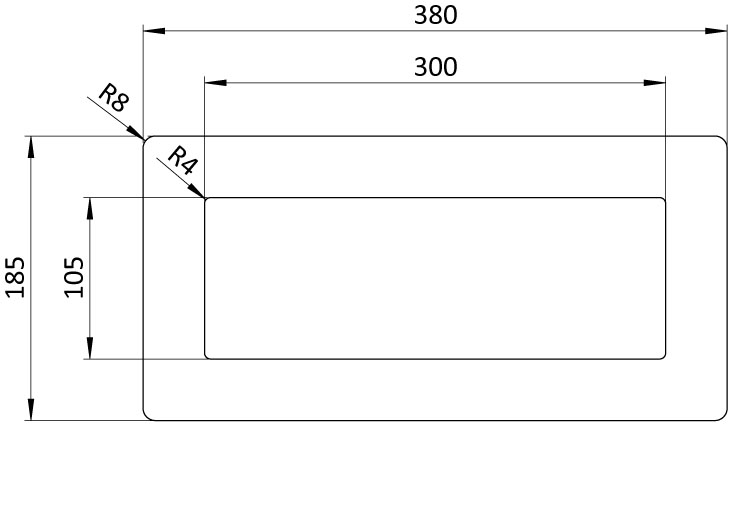

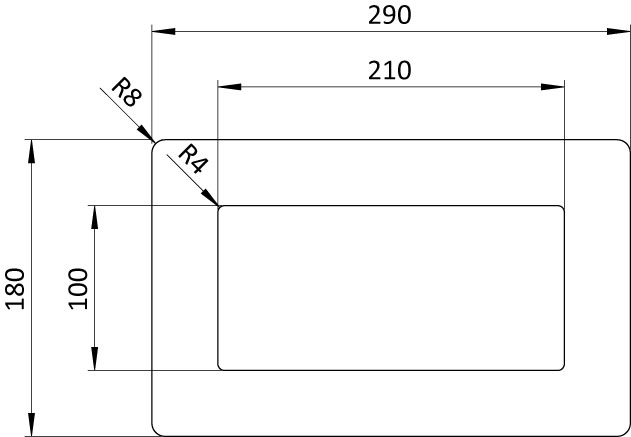

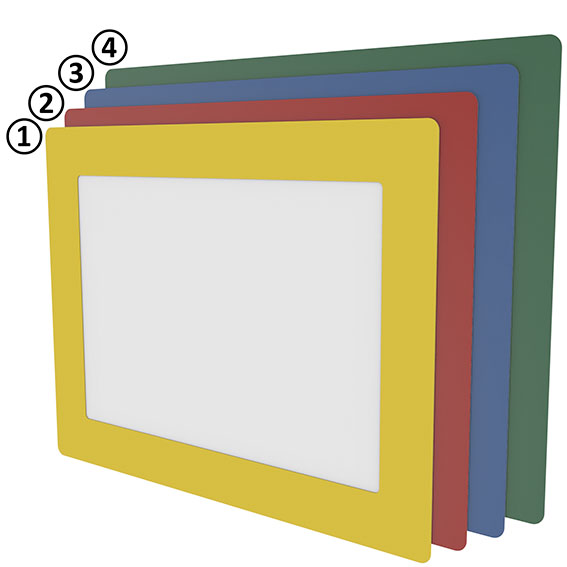

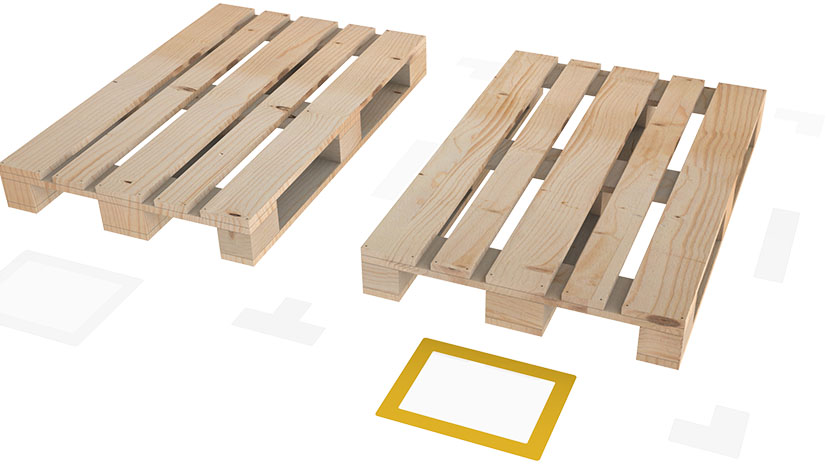

Lean production optimizes manufacturing processes to increase efficiency and reduce waste. This system integrates material flow, automation and continuous improvement methods to create a lean production environment. Products such as parking rails, guide rails and floor rollers play an essential role in optimizing material flow within lean systems. These components enable precise positioning, efficient transport and organized storage, which contributes to a smooth and effective production process.

Filter products

Core principles of lean production

- Added value: Focus on activities that generate direct customer benefit

- Continuous flow: Ensuring an uninterrupted production process

- Pull principle: Production only when actually needed

- Strive for perfection: Continuous improvement of all processes

Methods of lean production

- Kaizen: Continuous improvement through small but steady changes.

- 5S: Structured workplace organization for greater efficiency.

- Just-in-time: Production and delivery exactly when you need it.

- Kanban: Visual control of the material flow.

- Total Productive Maintenance (TPM): Holistic maintenance to maximize plant efficiency.

maunsystem: Your partner for lean production solutions

At maunsystem, you will find high-quality components that optimally support your lean production processes. Our products such as parking rails, guide rails, and floor rollers are specially designed to optimize material flow and reduce waste. Discover how our solutions can make your production processes more efficient.

FAQ

What is the main difference between lean production and traditional manufacturing?

Lean production focuses on the elimination of waste and continuous improvement, while traditional manufacturing often relies on mass production and warehousing.

How can lean production improve product quality?

By implementing quality controls in every process step and quickly identifying and rectifying problems, product quality is continuously improved.

What role do employees play in lean production?

Employees are crucial to the success of lean production. They are encouraged to actively participate in improvement processes and contribute their ideas.

How do maunsystem products support lean production?

maunsystem offers specialized components such as parking rails and floor rollers that optimize material flow and thus increase efficiency in lean production environments.