Material flow: optimization for efficient lean production

Material flow systems in lean production optimize the path of materials through the entire production process to increase efficiency and productivity. This includes the clear organization of storage, automated technologies such as conveyor belts and transport robots, as well as the continuous monitoring and adjustment of the material flow. These systems help to avoid bottlenecks, reduce costs and improve product quality.

maunsystem offers innovative solutions to improve the material flow in your company:

- Material flow analysis: We identify weak points and optimization potential.

- Lean concepts: Implementation of Kanban, just-in-time and other lean methods.

- Automation solutions: Customized systems for your specific requirements.

- Training: We enable your employees to continuously improve the material flow.

Filter products

Basics of the material flow

The material flow forms the backbone of efficient production. It encompasses all movements of raw materials, semi-finished products and finished products within a company. An optimized material flow is crucial for:

- Reduction of throughput times

- Minimization of stock levels

- Improving product quality

- Increase in overall efficiency

Lean production and material flow

Material flow plays a central role in lean production. The aim is to create a continuous, uninterrupted flow that is geared towards customer needs. Important principles are:

- Just-in-Time: Materials are delivered exactly when they are needed.

- Kanban: A visual system for controlling the material flow.

- One-piece flow: Production in the smallest possible batch sizes.

Optimization methods

Companies use various methods to improve the flow of materials:

- Value stream analysis: Visualization and analysis of the entire material flow.

- Spaghetti diagram: Recording material movements to identify waste.

- 5S method: Structuring and standardization of the workplace.

Technologies for an efficient material flow

Modern technologies support the optimization of the material flow:

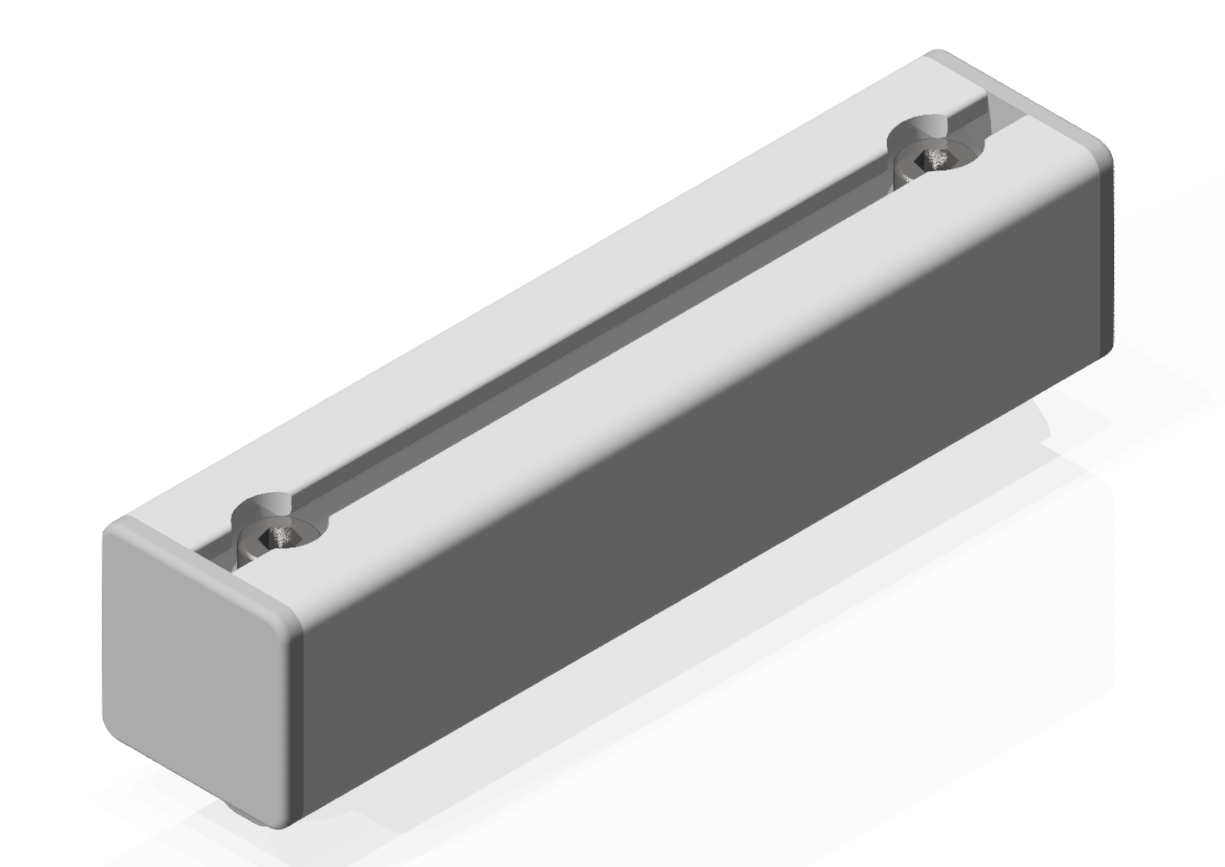

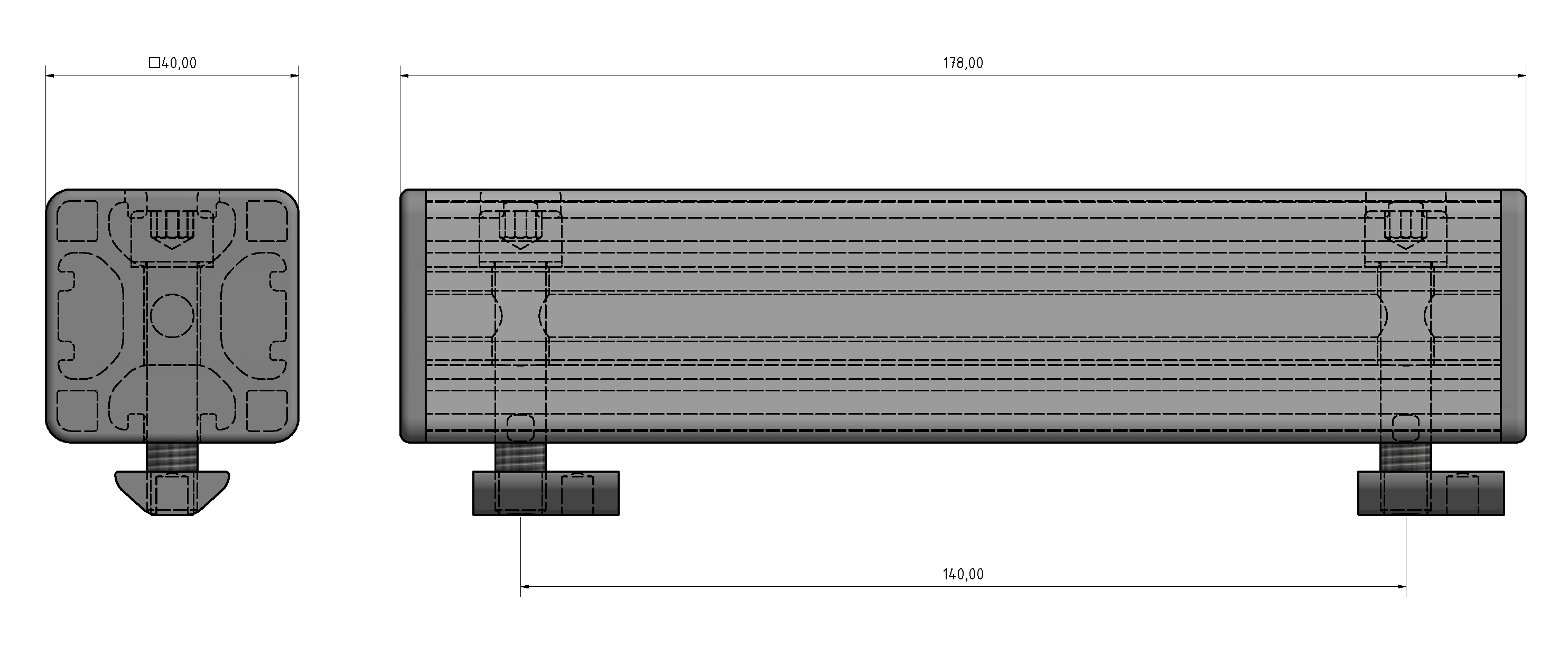

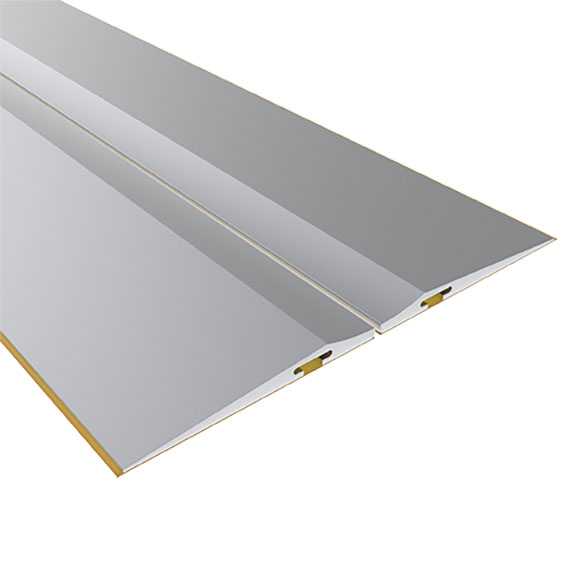

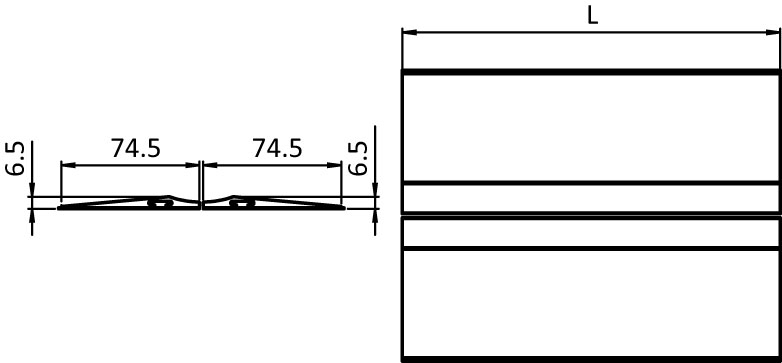

- Automated conveyor systems

- RFID tracking

- Intelligent storage systems

- Digital twins for simulation and optimization

maunsystem solutions for optimum material flow

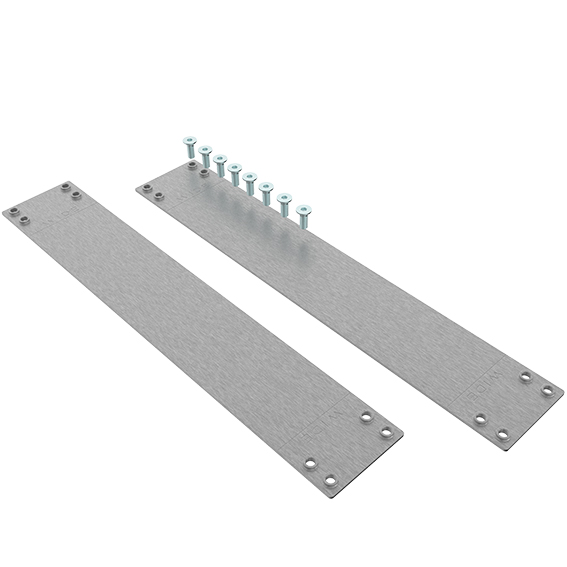

Optimize your material flow with tailor-made solutions from maunsystem. Our products are specially designed to increase efficiency and flexibility in your production.

FAQ on material flow

What is the difference between material flow and logistics?

Material flow refers specifically to the movement of materials within the production process, while logistics also includes external processes such as transportation and delivery.

How can I improve the material flow in my company?

Start with a thorough analysis of your current material flow. Identify bottlenecks and waste. Then gradually implement lean methods and use modern technologies for optimization.

What role does material flow play in Industry 4.0?

In Industry 4.0, the material flow is controlled by intelligent, networked systems. Real-time data enables flexible and efficient adaptation to changing production conditions.