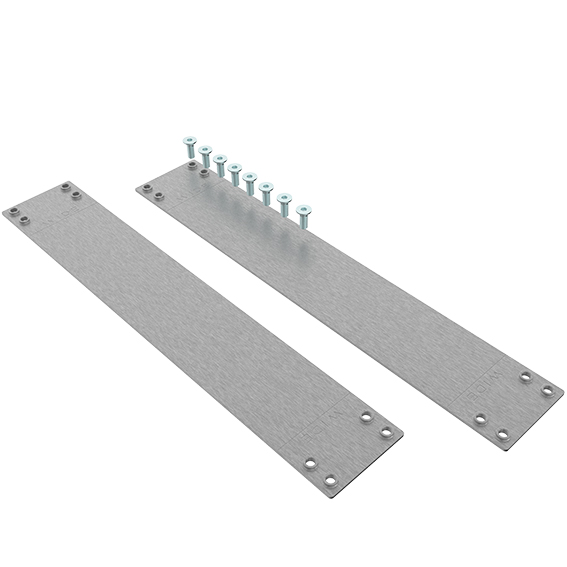

Guide rails: Indispensable components for efficient material flow systems

Guide rails are essential elements in lean production and play a central role in optimizing the material flow. At maunsystem, we offer high-quality guide rails that are characterized by their robustness, precision and flexibility.

FIFO guide rails: Innovation for the material flow

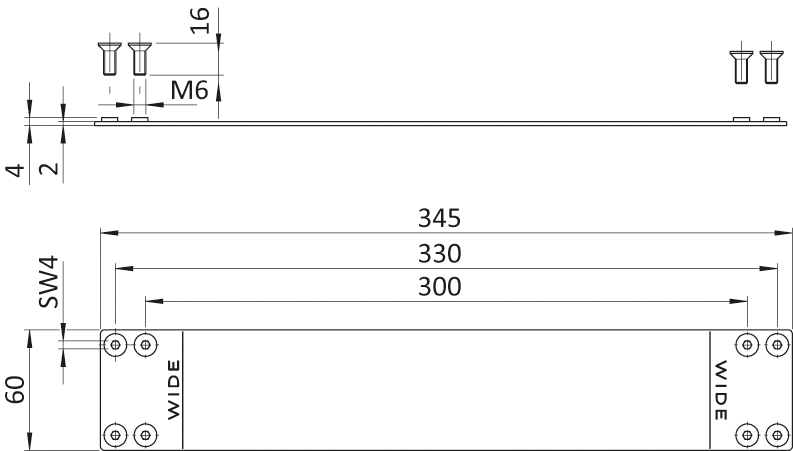

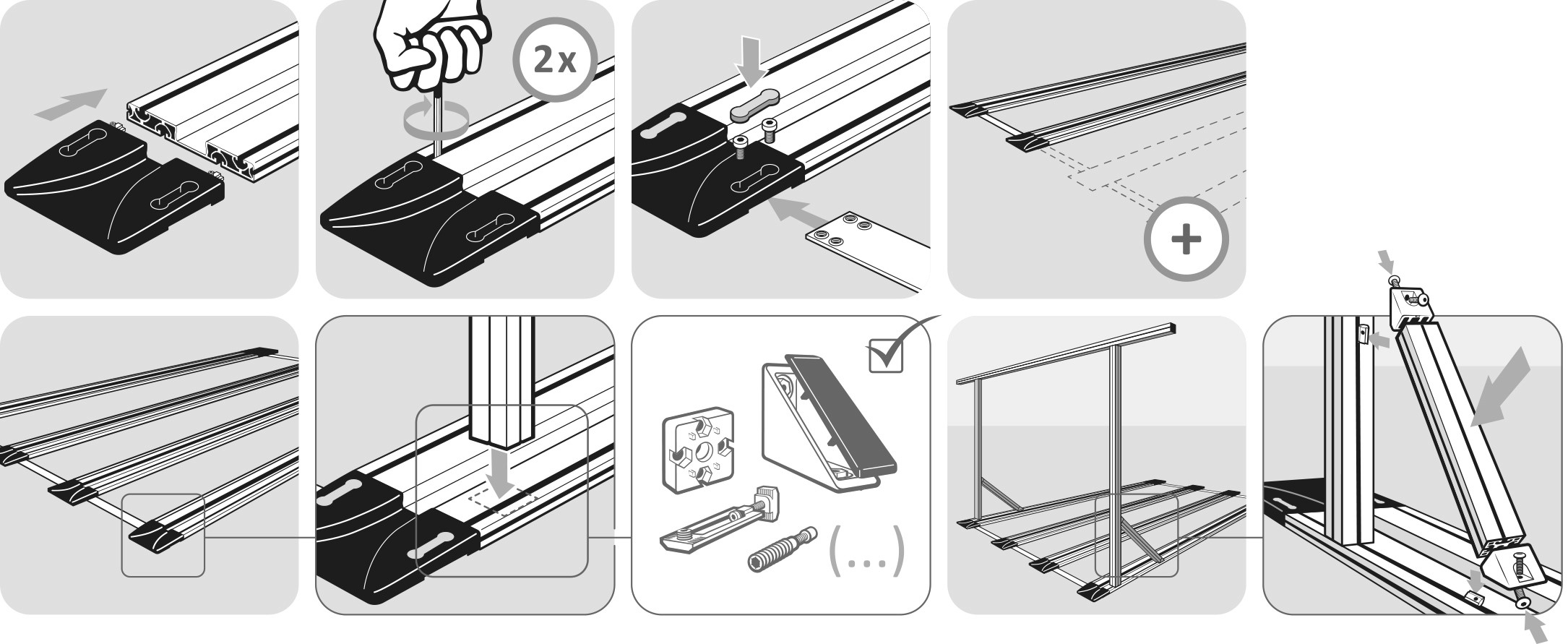

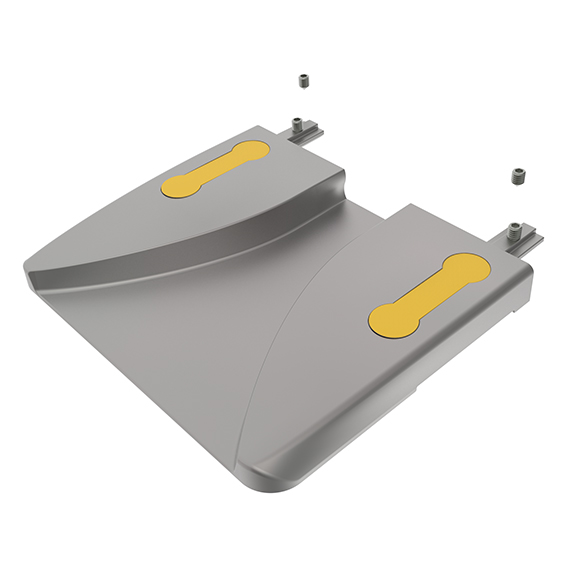

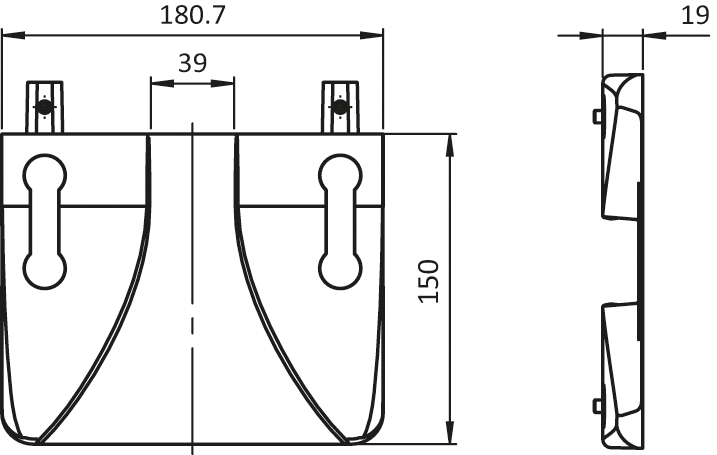

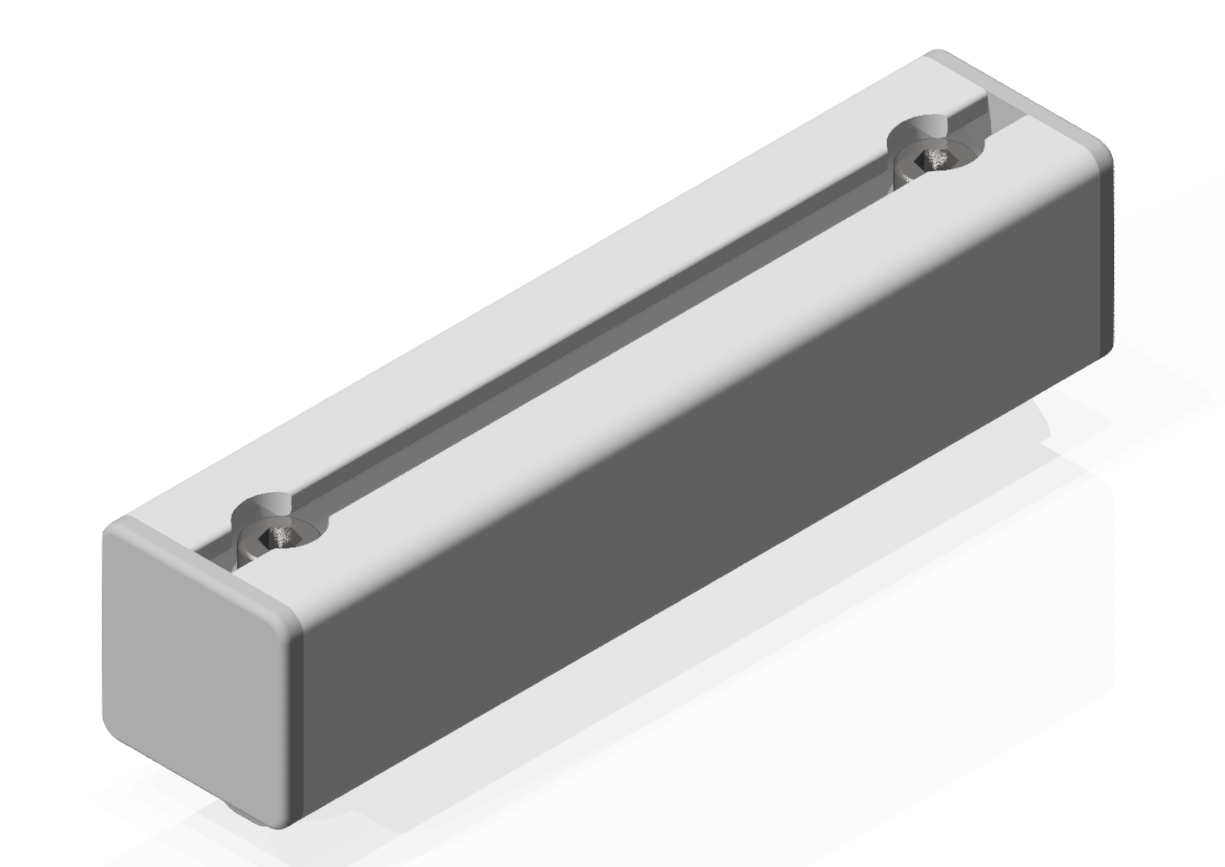

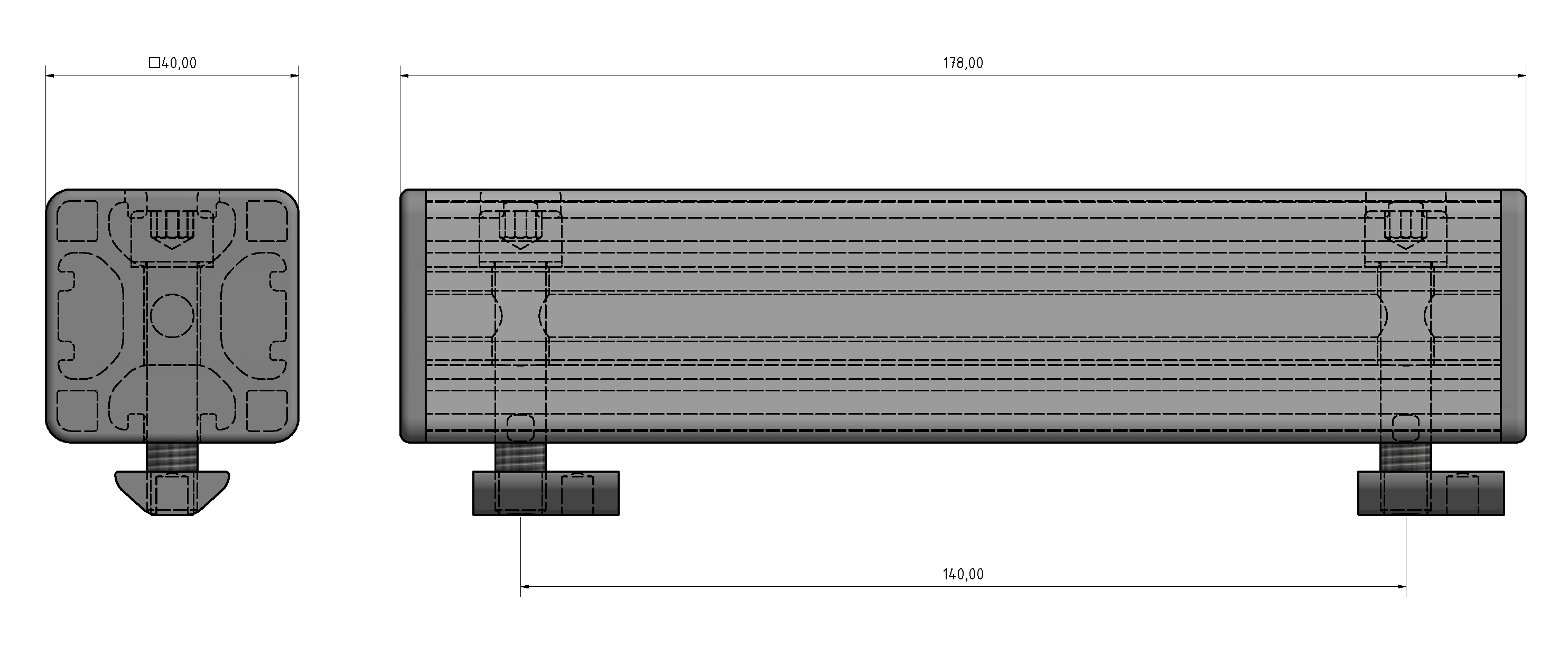

The maunsystem FIFO guide rails are installed floating, which means that the FIFO station does not need to be screwed to the floor. This protects the hall floor and enables easy installation. The rails are held in place by the weight of the floor rollers, ensuring a stable and safe solution. For special requirements, optional bolting to the floor is possible, with the holes already integrated into the insertion caps.

Filter products

Efficiency and cost savings

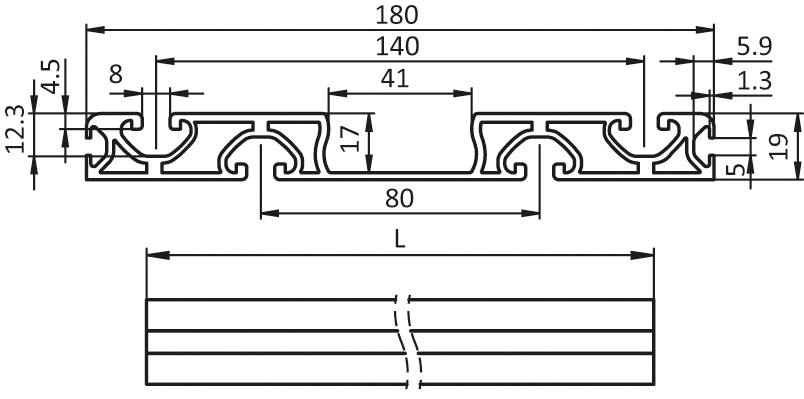

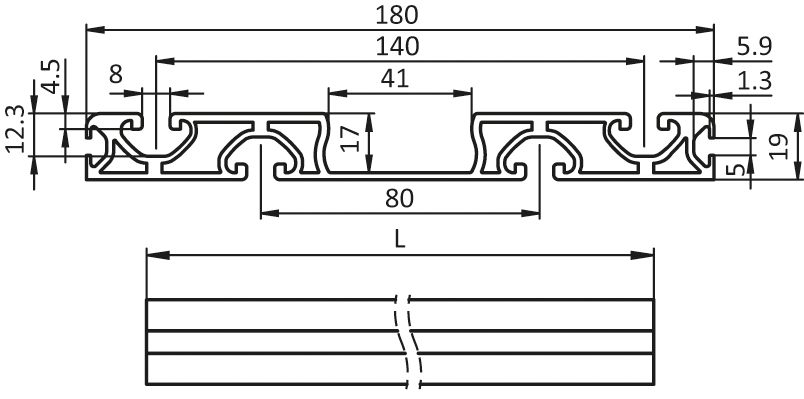

A major advantage of our guide rails is that only one guide rail per track is required for the safe positioning of the floor roller. The side on which the floor roller is guided is freely selectable. With three tracks, for example, only three guide rails are required. This not only reduces costs, but also saves space and offers additional flexibility in your material flow system.

Versatile areas of application

- Conveyor technology: Precise guidance of transport containers and pallets

- Warehouse logistics: Efficient organization of shelving systems

- Automotive industry: Support of assembly processes

- Packaging industry: Precise positioning of packaging machines

Quality and durability

Our guide rails are characterized by their high quality and durability. They are made from robust materials and can withstand even the most demanding industrial environments.

FAQ about guide rails

What is the difference between guide rails with and without deflection star?

Guide rails with deflection starwheels allow the guided elements to change direction, while rails without deflection starwheels are designed for straight-line movements.

What materials are used for guide rails?

Guide rails are often made of solid steel or in a laminated version, depending on the application and load requirements.

How do I choose the right guide rail for my project?

The choice of the right guide rail depends on factors such as the required length, the load and the specific area of application. Our team of experts at maunsystem will be happy to advise you on your choice.

Can guide rails be retrofitted?

Yes, many guide rail systems have a modular design and can be subsequently extended or adapted to meet changing requirements.

Discover our extensive range of guide rails and optimize your material flow with maunsystem. Our experts will assist you with the selection and implementation to make your production processes more efficient and cost-effective.